Prototyping + Testing

We put it to the test.

Utilizing our gated New Product Introduction (NPI) process, our engineering teams will:

- Work collaboratively with you to help develop your product specification

- Create a 3D concept product design to meet your unique specifications

- Analyze the product concept using FEA, DFMEA/PFMEA, and other analytical tools

- Create a prototype and conduct testing in our state-of-the-art product development lab to verify the design

- Manage the supply chain and manufacturing process to ensure low-cost, unparalleled quality and on-time delivery

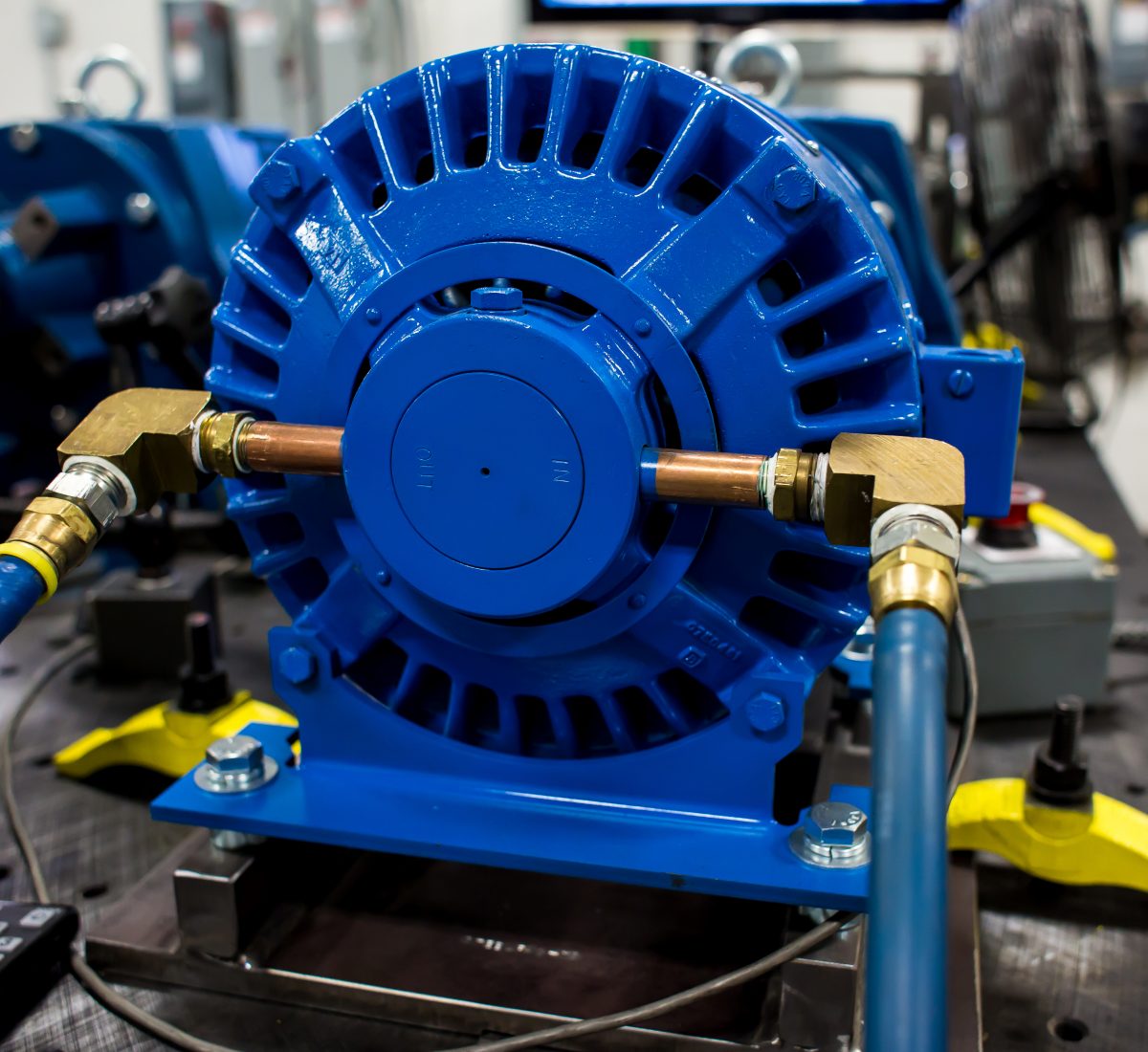

Measurement Capability

- High Accuracy displacement & motion

- Torque

- Operating temperatures

- Efficiency

- Vibration

- Basic noise

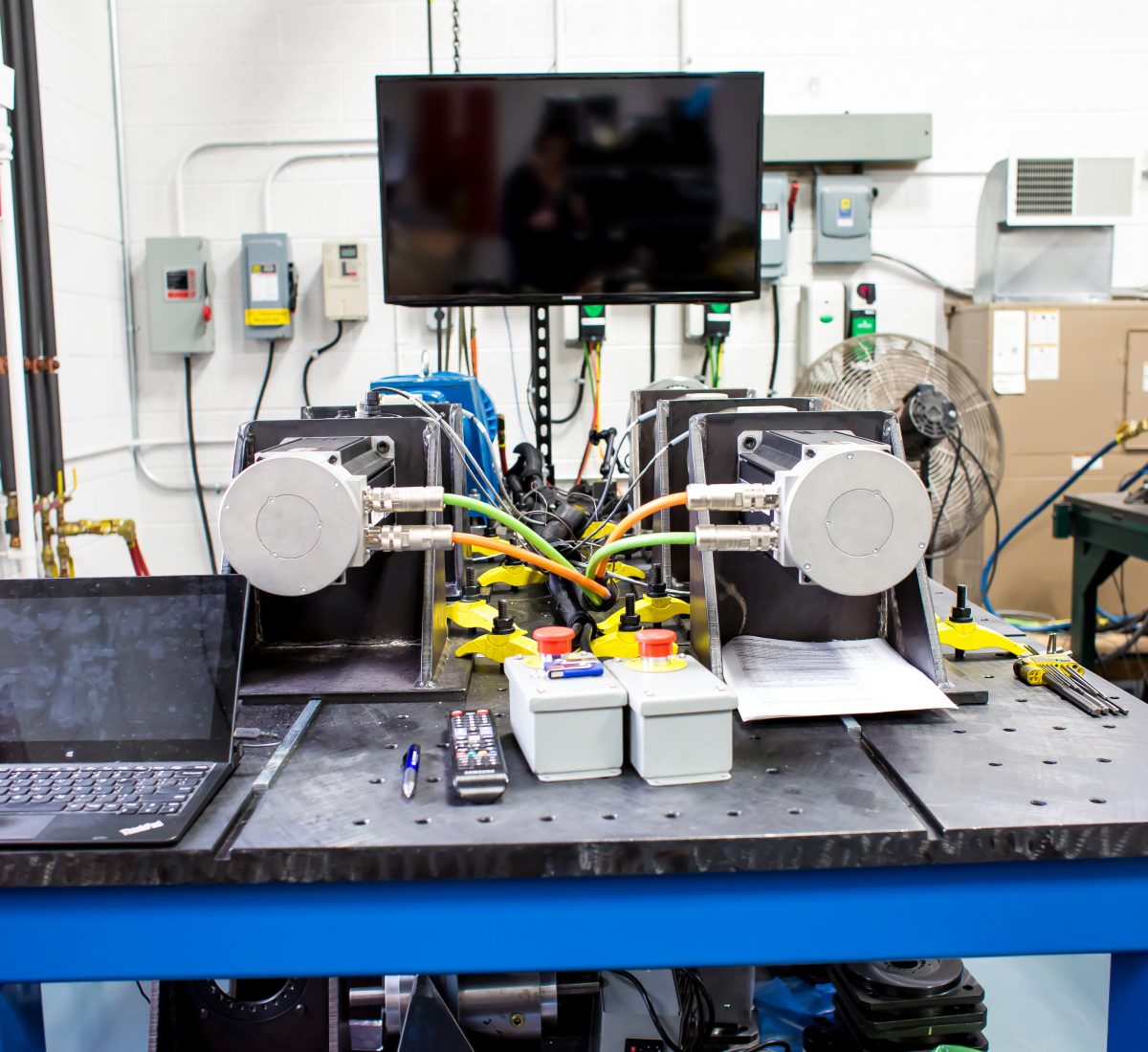

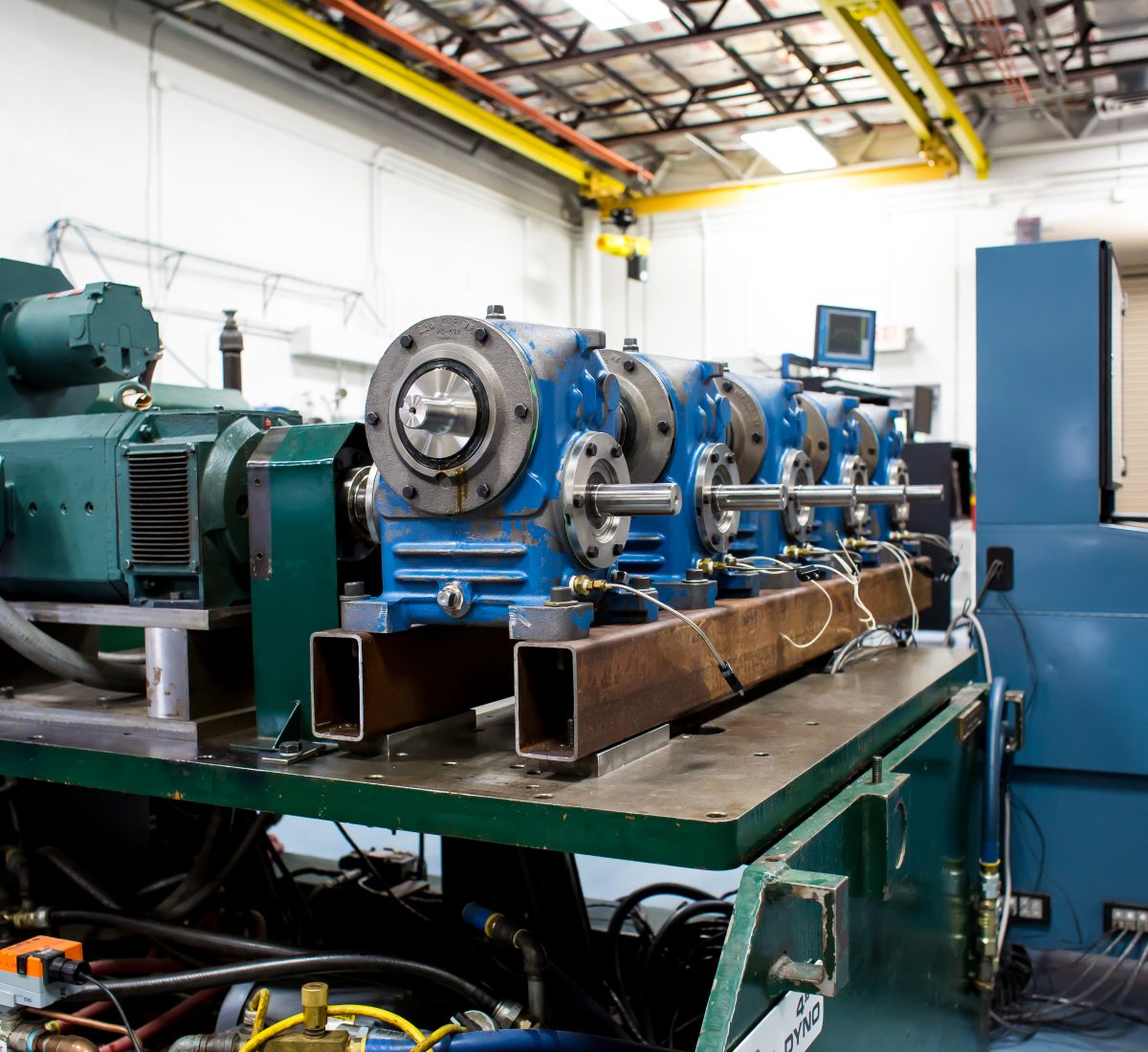

Testing Facilities

- 13 flexible product test stands

- High speed data acquisition

- Automated control for 24hr operation

- Servo control

- Inertial loading

- Constant torque/load

- High static load

- High resolution position monitoring

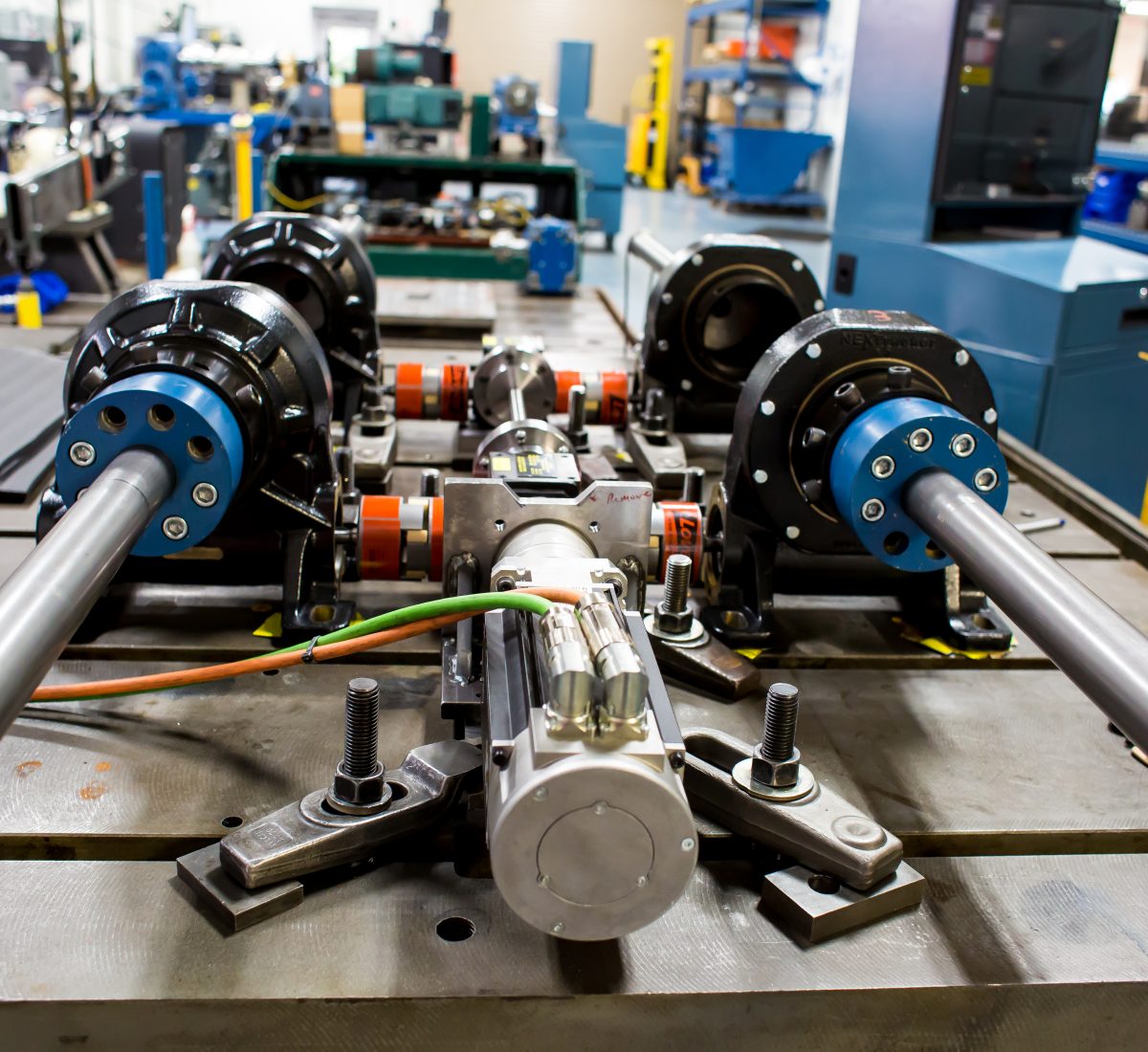

Testing Capabilities

- Thermal analysis

- Transmission accuracy and smoothness

- Power capacity & operating efficiency

- Durability & accelerated life testing

- Structural stiffness

- Simulated inertial loading & cyclic control

- Customized test design