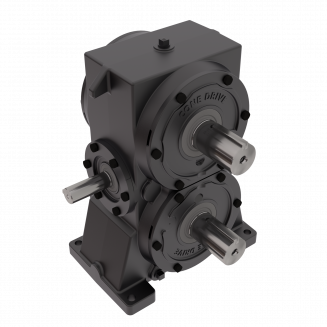

DuoDrive

Talk about torque.

Pinch-roll reducers use a single input worm to turn two gears simultaneously in opposite rotations for use in applications such as cold-roll forming, tube milling, and wire milling where very high torque is required to smoothly propel metal through high pressure mill rollers. The Duo Drive is presented with several thermal control solutions, such as finned housings, fan cooling, and liquid cooling to ensure that your process runs as smoothly and efficient as possible.

Key Features

- Sizes (center distance, inch) : 2.0 – 15.0

- Standard Reduction Stages: Single, double

- Interface: Inch or metric

- Output Torque: Up to 480,646 (54,310 Nm)

- Gear Ratios: Up to 4,900:1; unequal ratio available

- Input Options: Solid shaft, NEMA interface

- Output Shaft Options: Solid, hollow

The Duo Drive is proudly made in the USA.

Download Overview

Download Overview